| Hampden Engineering | Heathkit |

|

Fractional Distillation Trainer

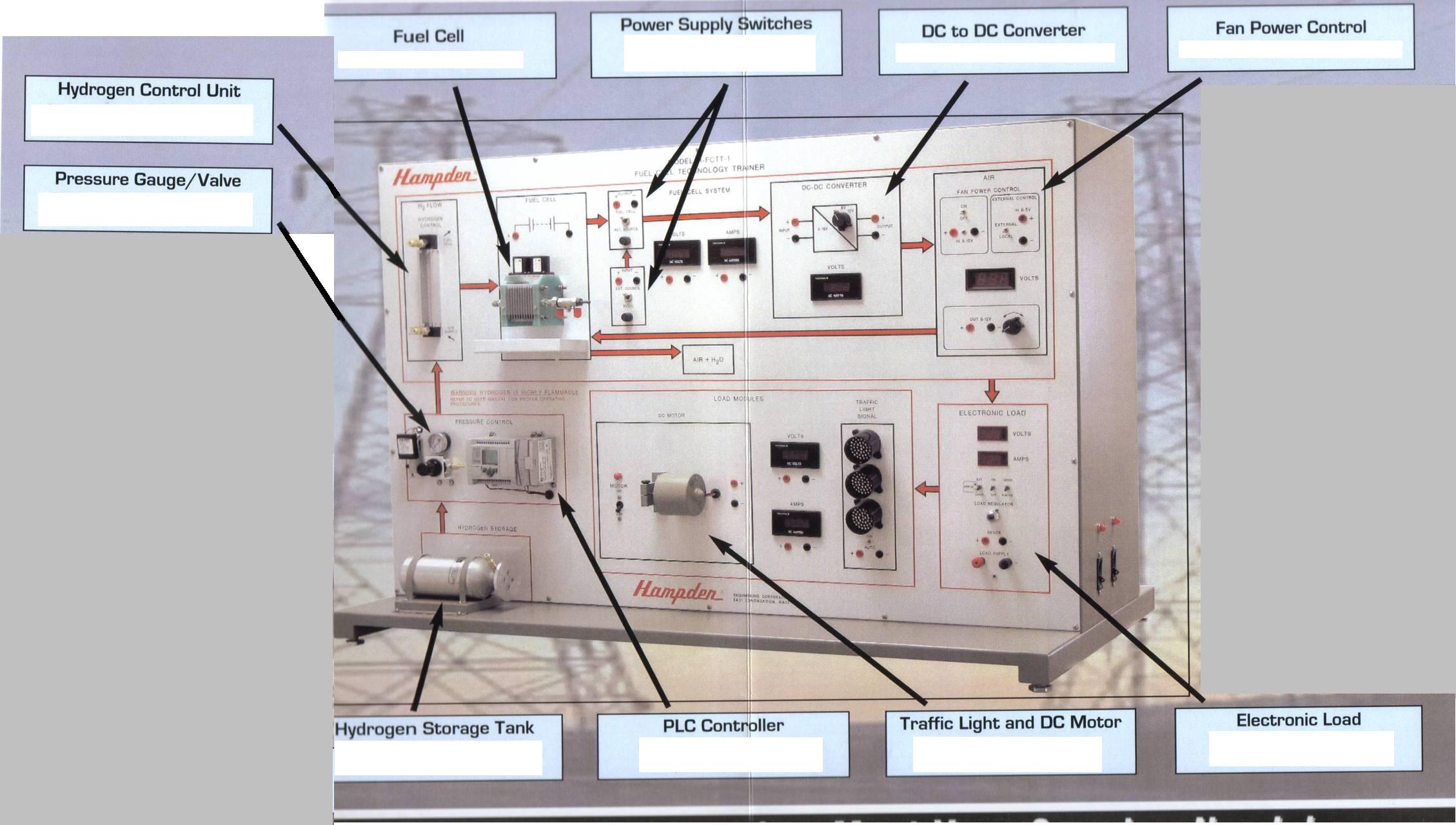

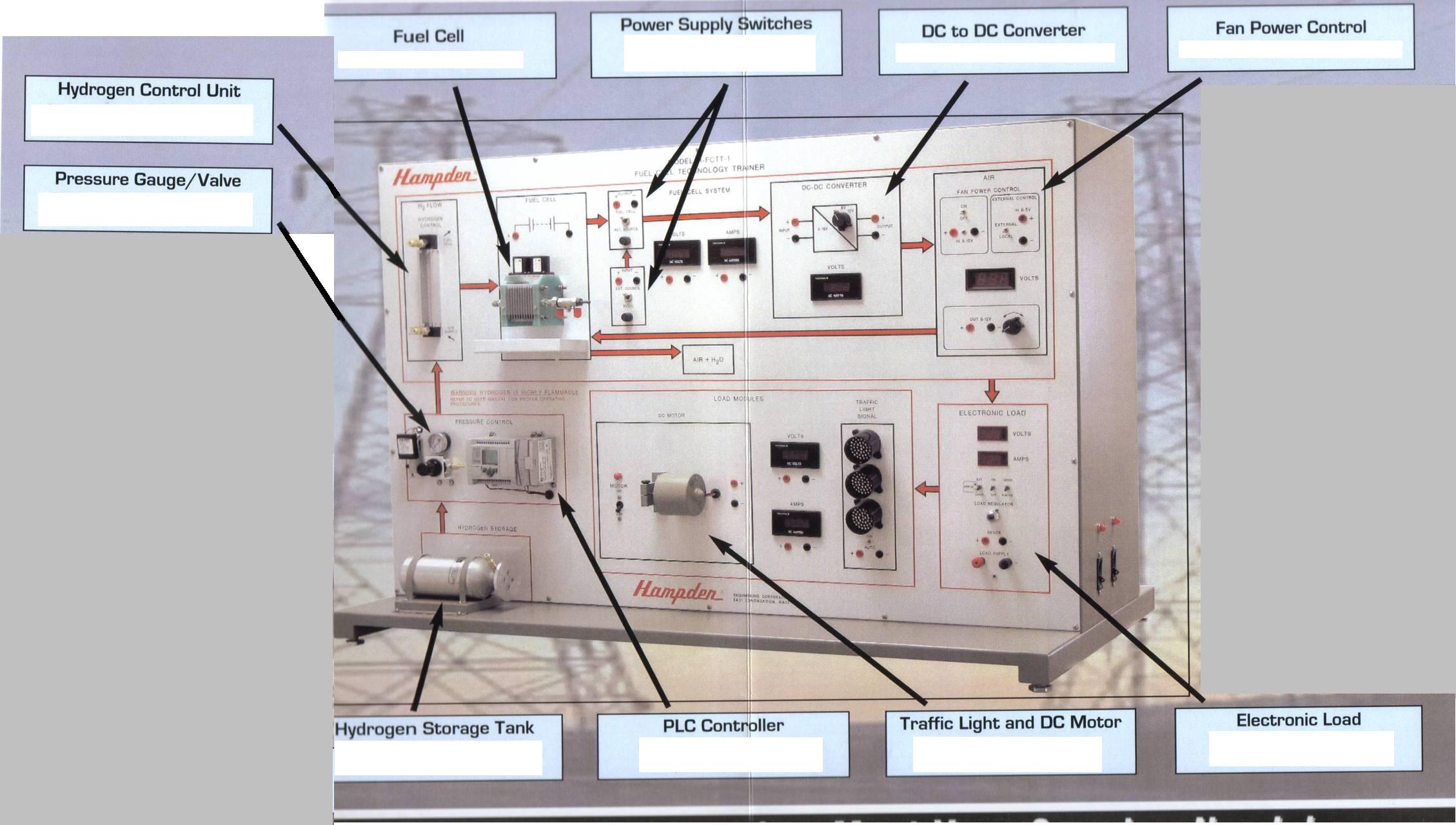

The Hampden Fuel Cell Technology Trainer allows the student to create a grid independent power supply that uses only hydrogen as its fuel. The system familiarizes the student with fuel cell power supply technology, an environmentally friendly method of generating power directly from a hydrogen reaction.

Fuel cells are the most promising alternate energy supply and are already being used in a number of areas, including automotive engineering and power generation systems. The trainer can also be connected to an external energy source, such as a solar panel for wind generator for comparison between the different technologies. A switch located on the panel allows for switching between the fuel cell and an eternal source. |

The conservation of environmental resources is one of today’s hot topics. As our natural resources dwindle, finding alternative, or eco-friendly, solutions to energy and consumption has become the cornerstone in the conservation effort. Solar panels, hybrid cars, thermoelectric watches and hydro - powered machines are just a few examples of this effort. The concept behind all of these products is renewable energy.

Heathkit's Educational Systems’ Renewable Energy course introduces students to the principles of thermoelectricity, solar cells and fuel cells (renewable energy). Through a series of hands-on experiments, students will learn the fundamentals and applications of renewable energy, and how it fits into the real world of today

|

H-61 73

Fractional Distillation System

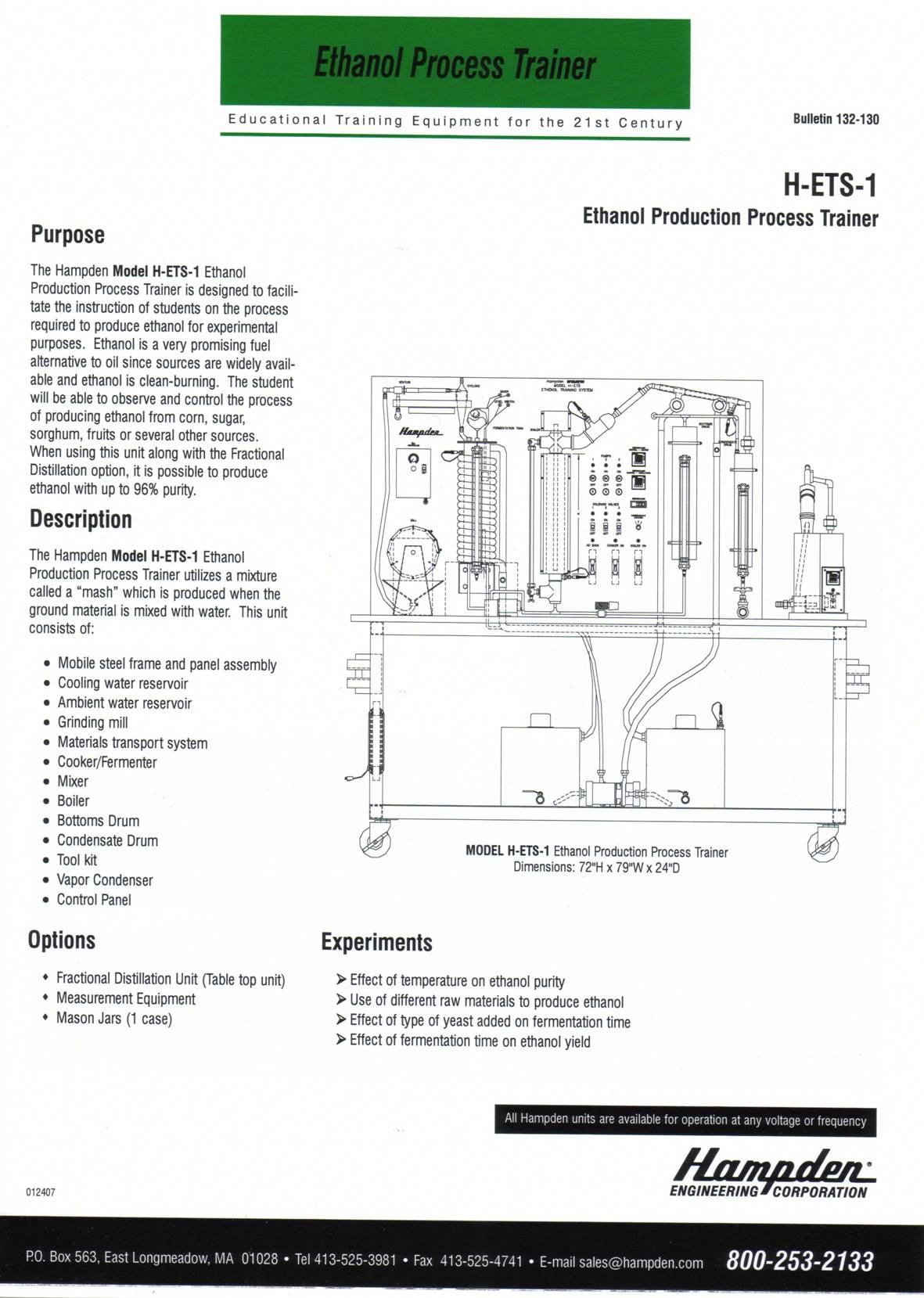

The Model H-6173 makes educational and industrial experimentation possible in a virtually limitless range—from simple steady-state binary separations to highly sophisticated process dynamics research including column hydraulics and packing materials. Even bench-scale pilot production runs are feasible with appropriate modifications.

Major components of Model H-6173 are:

· Ten-gallon feed reservoir

· Feed pump

· Feed preheater

· Liquid-level and overheat controlled boiler

· Plate-type and packed-type columns

· Glass-walled, water-cooled, shell-and-tube

type condenser providing 1-1/2 ft2 of tube

surface

· Glass-walled distillate reservoir

· Reflux pump

· Reflux preheater

· Coolant rotameter

· Boiler, feed & reflux preheater temperature controls

· Twelve Chromel-Alumel thermocouples with thermocouple selection switch

· Pump heater & main power ON-OFF switches

· Voltmeter and Ammeter

· 72-inch manometer

· Necessary valves

· Quick-couple flexible hoses

· Operating Manual with experiments

Application

Because of its compact size, relatively large capacity boiler, relatively large condensing tube surface and versatile rapidly-manipulable feed and measurement hardware, this system possesses considerably more flexibility than conventional laboratory fractional distillation equipment. Changes in operating conditions are quickly effected and column response is rapid. Students, teachers and industrial researchers are able to collect more pertinent data in a shorter time than with conventional equipment and carry exploration into distillation phenomena and processes further and at a lower cost.

The effects of vaporization, condensation and liquid-vapor mixing—relative to the separation of volatile liquid systems by the application of heat—are observed and measured under the dynamic conditions of column operation.

The Model H-6173 is mounted on casters and requires only water and electrical connections for operation. Because the unit has very rapid response and glass column walls, it is also

used effectively in lecture demonstrations.

The unit is designed for closed-loop operation with feed and product streams cycled through a common reservoir tank. However, it can be arranged to effectively separate a feedstream with separate distillate and bottoms product. Both in appearance and in operation, thecolumns are faithful replications of commercial columns. The unit does provide means for experimental external manipulation of certain internals such as the heights of the weirs and downcomers used in the plate-type column. Means are also provided for introducing feed and reflux streams at any of several pertinent locations for: obtaining liquid and vapor samples at critical locations, picking up critical temperatures and pressures, and measuring feed and reflux flows and distillation rates. Feed and reflux streams are continuously variable from zero to total.

Experiment Capabilities

Model H-6173 will accept a wide variety of liquid systems. The unit is physically versatile and readily modifiable for open loop or cascade type processes. These design qualities make experimental capabilities virtually limitless, even though it is not designed for cryogenic or high-pressure fractionations.

Basic Technology

Plate Column Separations, evaluations of: Hydraulics

Pressure drops

Efficiencies

Effects of feed plate locations, boil-up rates, reflux ratios, plate geometry

Packed Column Separations, evaluations of: Pressure Drop

Efficiency

Types of Packings

Effects of Boil-Up Rates, Reflux Ratios, Packing Geometries

Separations By Either Type Column, determinations of:

Mass Balances

Thermal Energy Balances

Physical and Chemical Characteristics of Feeds, Reflux, Products

General Learning:

Calibration of Rotameters, Thermocouples Operation of Liquid-Level and Temp Controls Operation and Heat Transfer Efficiency of Shell and Tube Type Condensers

Advanced Distillation

With respect to either type column:

Continuous Multi-Component Distillation Multi-Component Batch Differential Distillation Multi-Phase Distillation

Steam Distillation

Heterogenous Azeotropic Distillation Homogenous Azeotropic Distillation Extractive Distillation

Transient Operation

Process Dynamics And Control Distillation Process Fundamentals With respect to either type column:

Continuous Binary Stripping Continuous Binary Rectification Continuous Binary Fractionation Binary Batch Differential Distillations

|

|

|

|

|

|